Porsche has begun upgrading its main plant in Stuttgart-Zuffenhausen to cater to a more efficient production process for its future models. The process will include bringing more automation into the production process, adding improved quality checkpoints, and improving body shop logistics. One of the main aims of these upgrades is to enable mixed production of internal combustion engine (ICE) models and EVs. To this end, Porsche is working on enabling the future electric versions of the next-generation 718 line-up to be produced on the existing assembly lines alongside Porsche’s current two-door ICE models (the 718 Cayman, 718 Boxster, and the iconic 911 are assembled exclusively in Zuffenhausen). This will likely offer better flexibility and help increase the production capacity.

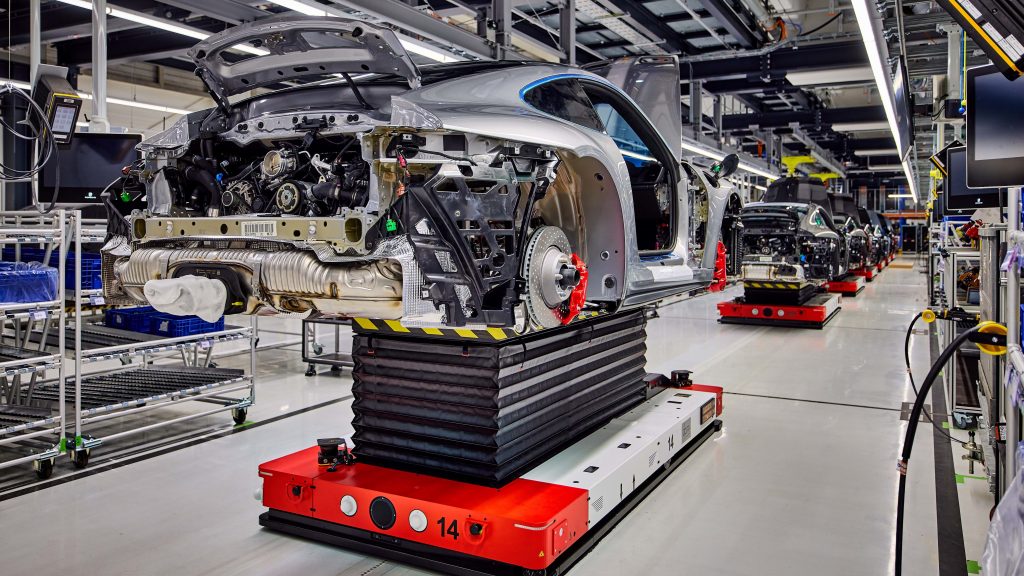

For the integration of new production phases, the production line area for two-door models has been increased. The traditional assembly line will also be replaced with a ‘Flexiline’ that uses the latest generation of automated guided vehicles (AGVs). The use of AGVs was implemented by Porsche for the production of the Taycan. As the name suggests, AGVs do not require human intervention and are much more efficient and flexible when it comes to mixed production (production of different types of models on the same line). They can also be very advantageous for the production of custom-specified models (Porsche offers a wide array of customisation options for its vehicles. In the process, most Porsche cars end up rolling off the production line as one-offs).

For improved quality management, Porsche has introduced standardised quality assurance and approval checkpoints at the end of the assembly process. This includes the addition of a new light tunnel for paint quality and final inspection, adapting the acoustic test benches for EVs, and revamping leak and surface inspection test benches as well.

Work on expanding the logistics areas within the body shop has been in progress since 2022, with a completion deadline of 2025. This involves the addition of a new building which will house high-bay storage racks extending over two floors.

Work is also underway to integrate the assembly operations of the upcoming electric Macan’s powertrain into the existing V8 engine plant at Zuffenhausen. Like the current generation, the next generation of the Macan will also roll off the production line at Porsche’s Leipzig facility in 2024.