Factorial Inc., a leader in solid-state battery technology for electric vehicles (EVs), has announced a significant milestone in its partnership with Mercedes-Benz. The company delivered B-samples of its 106+Ah lithium-metal solid-state battery cells to the German automaker, marking the first announced shipment of such cells to a global automotive original equipment manufacturer (OEM). This development represents a crucial step towards the commercial production of EVs equipped with Factorial’s advanced battery technology.

The B-samples’ delivery follows Factorial’s shipment of over 1,000 100+Ah solid-state battery cells to Mercedes-Benz during the A-sample phase. This previous phase demonstrated Factorial’s ability to produce high volumes of large-format solid-state batteries. The B-samples will now be integrated into modules and battery packs for comprehensive testing and optimisation, validating their design against Mercedes-Benz’s stringent performance standards.

Accelerating innovation

Factorial CEO and Co-Founder Siyu Huang expressed excitement about this advancement, stating, “We are thrilled to advance to the B-sample phase with a global automotive leader like Mercedes-Benz. This swift progression from A-sample to B-sample delivery in under a year highlights Factorial’s rapid innovation capabilities.” Huang emphasised that their high energy density cells will contribute to creating more efficient and sustainable vehicles, setting new standards for EV range, cost, and performance globally.

Technical specifications and advantages

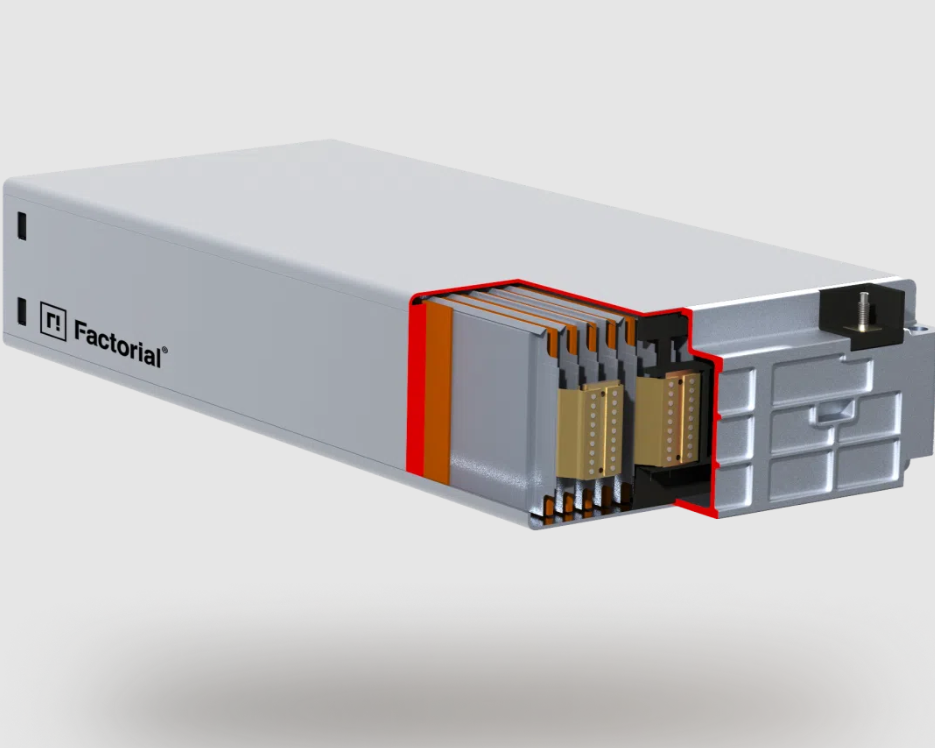

Factorial’s solid-state batteries are built on its proprietary FEST® (Factorial Electrolyte System Technology) platform, which features a lithium-metal anode. This anode, being the lightest metal on earth, enables the high energy density of 391Wh/kg. Additionally, the batteries are manufactured using existing lithium-ion battery production equipment, requiring minimal modifications. This approach is expected to streamline the manufacturing validation process and significantly reduce long-term operating costs.

Mercedes-Benz’s strategic commitment

Markus Schäfer, Member of the Board of Management at Mercedes-Benz Group AG and Chief Technology Officer, highlighted the importance of this collaboration. “We are committed to leading in innovative battery technologies, and our partnership with Factorial is a significant part of this strategy,” Schäfer said. He added that the B-sample batteries provide an opportunity to validate next-generation battery technology further, with goals to enhance range and performance, reduce vehicle costs, and offer desirable electric vehicles to customers.

Broader industry impact

This milestone reinforces Factorial’s position as a key technology partner for automakers seeking advanced battery solutions to enhance their EV portfolios. In addition to Mercedes-Benz, Factorial has joint development agreements with Stellantis, Hyundai Motor Company, and Kia Corporation. These partnerships underscore the automotive industry’s recognition of Factorial’s innovative approach to battery technology.

Addressing industry challenges

The move towards solid-state batteries addresses several challenges faced by the EV industry, including the need for higher energy density, improved safety, and reduced costs. Factorial’s technology promises to extend the driving range of EVs while maintaining safety and efficiency. The collaboration with established automakers like Mercedes-Benz is crucial in bringing this technology from the lab to the road.

The delivery of B-samples to Mercedes-Benz marks a significant step forward in the development and validation of solid-state battery technology. This progression underscores the rapid innovation in the EV sector and highlights the collaborative efforts needed to achieve sustainable transportation solutions. As Factorial continues to develop and optimise its battery technology, its partnerships with leading automakers will be vital in accelerating the adoption of more efficient and cost-effective electric vehicles.