Cleaner mobility has been at the forefront of the automotive landscape for nearly a decade, and constant innovations in the automobile domain promise a carbon-neutral future. One of the most popular future mobility solutions is electric vehicles, which have seen a huge transformation in the past couple of years. We have seen a ubiquitous shift from lead-acid and nickel-metal hydride batteries to Li-ion batteries. We are now surrounded by Li-ion batteries — from your mobile phone to your electric vehicle — you can find them in nearly every electronic device in today’s day and age. However, there is another emerging battery type that claims to be safer and more efficient than Li-ion batteries and it’s called solid-state batteries.

In this article, we take a deep dive into solid-state batteries, decode their characteristics and understand why they aren’t mainstream yet.

What Is A Solid-State Battery?

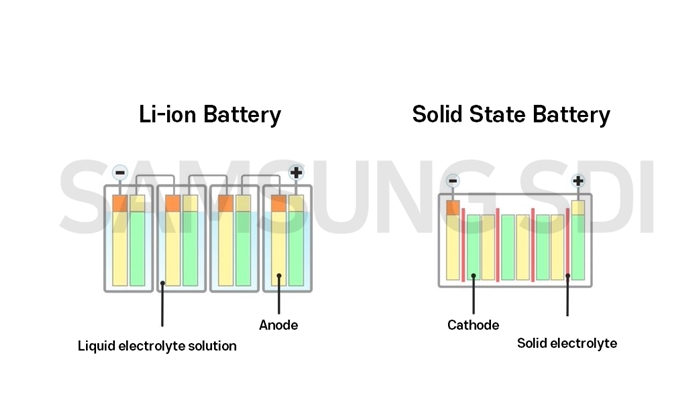

Like every other battery, a solid-state battery also has three components – anode, cathode and electrolyte. A solid-state battery uses a solid electrode and a solid electrolyte, which also doubles up as a separator component. The lack of a primary separator component and liquid- or gel-based electrolytes make the solid-state batteries considerably compact, efficient and safer than any other battery chemistry in the industry. Reports suggest that solid-state batteries could deliver 2.5x more energy density compared to the regular Li-ion equivalent.

Here is a diagram comparing the size of a Li-ion and solid-state battery having similar capacity:

How Is A Solid-State Battery Different From A Li-Ion Battery?

If we compare a solid-state battery with the current industry-standard Li-ion battery, there are mainly 2 differences. First is the solid electrolyte used in solid-state batteries over a liquid- or gel-based electrolyte used in Li-ion batteries. The use of a solid electrolyte makes solid-state batteries more compact, spillage-free and considerably less inflammable compared to Li-ion batteries.

Secondly, solid-state batteries do not comprise a separator, which (as the name suggests) separates the electrodes of the battery. Li-ion batteries, on the other hand, use a separator taking up considerable space in every cell. The lack of a separator in a solid-state battery considerably reduces its size while maintaining overall functionality and efficiency.

Since there are so many advantages of a solid-state battery, you may wonder, why aren’t they mass-produced yet? We try to understand just that.

Why Solid-State Batteries Aren’t Mass Produced Yet?

Multiple start-ups across the globe funded by renowned manufacturers like Volkswagen, Hyundai, Honda etc are tirelessly working towards the mass-production of solid-state batteries. The concept of solid electrolytes harks back to the 1980s when it was first invented. However, its development took a backseat due to multiple constraints until the rise of electric vehicles heralded into the automotive industry in the 2010s. There is no definitive answer as to why solid-state batteries aren’t the preferred choice for carmakers when their characteristics claim to be one, apart from the early development phase, high production cost and complexity.

Solid-state batteries are undergoing constant improvement and many start-ups funded by auto giants are aiming for mass production of SSBs from 2024. One such example is QuantumScape which announced to mass produce solid-state batteries from H2-2024 onwards. Auto giant Volkswagen and veteran investor Bill Gates have infused their capital into the startup and naturally enough, the German auto group will be the first recipient of these batteries.

Honda is another auto giant that has been developing an all-solid-state battery (ASSB). While carmakers like Volkswagen and Toyota are relying on partners for the development of solid-state batteries, Honda has chosen to develop the tech in-house and later use these batteries in their production of electric models. Honda is said to begin the mass production of its ASSBs by March 2024.

Toyota Joins Hands With Idemitsu To Mass Produce SSBs

In the latest development, Toyota has joined hands with Idemitsu to collaborate on the mass production pilot project for all-solid-state batteries (ASSB). Under the collaboration, both companies aim to successfully commercialise solid-state batteries for battery electric vehicles (BEVs) by 2027-28. The collaboration focuses on sulphide solid electrolyte, which is said to be a promising material to achieve high capacity and output for BEVs.