Elon Musk recently asserted that AI (Artificial Intelligence) will eventually create a situation where ‘no job is required.’ Intrigued by this notion, I conducted an experiment, engaging AI to design an 8-seater electric vehicle. Before delving into that, let me provide some context.

As a serial entrepreneur, I established my EV startup in 2017, a time when Tesla grappled with challenges, and success stories in the EV realm were scarce. Despite this, I remained steadfast in my conviction that the ICE-based automobile industry would undergo disruption via electric drivetrains. I saw such disruptions as opportunities for new entrants to capture market share. Moreover, my deep-rooted purpose to make a positive social and climate impact through clean mobility propelled me forward.

One of the most daunting realisations was the typical vehicle development timeline, spanning from the inception of an idea to product production, which typically exceeds 6 years. For a startup to survive such a prolonged period before product launch poses significant challenges. Nonetheless, akin to most optimistic entrepreneurs, I maintained the belief that expedited timelines were achievable.

Before incorporating Sooorya EV in 2017, I dedicated a year to studying the automobile industry. Over the subsequent 6 years, I learned extensively, accumulating over 10,000 hours—an experience akin to a potential Ph.D.

Gradually, I comprehended that achieving PMF (Product Market Fit) holds more significance than merely expediting the launch process. However, the challenge remained: how could we hasten the development process and curtail costs?

Beginning from market research, benchmarking, and outlining product specifications to the stages of Design, Engineering, and Production, every step demanded time. To gain market insights and a comprehensive understanding of PMF, I traversed and test-drove across five continents. This was imperative given the market distortion caused by monopolistic automakers selling vehicles with features redundant in certain markets.

For instance, in Singapore, numerous cars sold there are equipped for snowy conditions, incorporating features like heated steering and seats, defrosters, and heaters—features never utilised in that climate. Similarly, with a speed limit of 90 km/h in Singapore and hefty fines for over-speeding, a significant portion of the vehicle’s performance remains redundant. This scenario results in consumers paying for features they will never use.

Returning to the Design stage, it remains time-consuming, predominantly reliant on a manual process, commencing from hand-drawn sketches to renders. While a substantial portion is digitally produced, the core artistic talent of designers remains crucial in creating these sketches and renders.

Nevertheless, witnessing the transformation of an idea into a sketch brings immeasurable joy. Not only does the sketch facilitate communication through its visual representation, but it also expedites work on specifications. Yet, the challenges and hurdles for an EV startup to progress in a monopolistic industry, dealing with suppliers accustomed to large corporations, remain a source of agony and pain.

The COVID-19 pandemic heralded a change: sales slumped for legacy automakers, ‘Work From Home’ became the norm, and automobiles receded from the roads, leading to a visibly improved environment—clear blue skies and fresher air. Consequently, more suppliers displayed a willingness to engage, recognising the imminent disruption in the legacy automobile industry, foreseeing an electric vehicle-dominated future.

In the prolonged process of automobile design, ‘Clay Models’ of vehicles persist despite the availability of 3D imagery. These physical models serve to enhance the realism of the design, aiding in better visualisation, understanding dimensions and space, and evaluating the aesthetic appeal or aerodynamics.

Today, a significant portion of the work is digitally executed, leveraging new tools such as immersive 3D, augmented reality, virtual reality, and simulations, facilitating iterative design and development.

Witnessing a digital 3D image of the conceptual vehicle marks a substantial leap forward in the vehicle development process, albeit taking a couple of years to reach this stage. Decisions on EV drivetrains, batteries, and their influence on design need careful consideration.

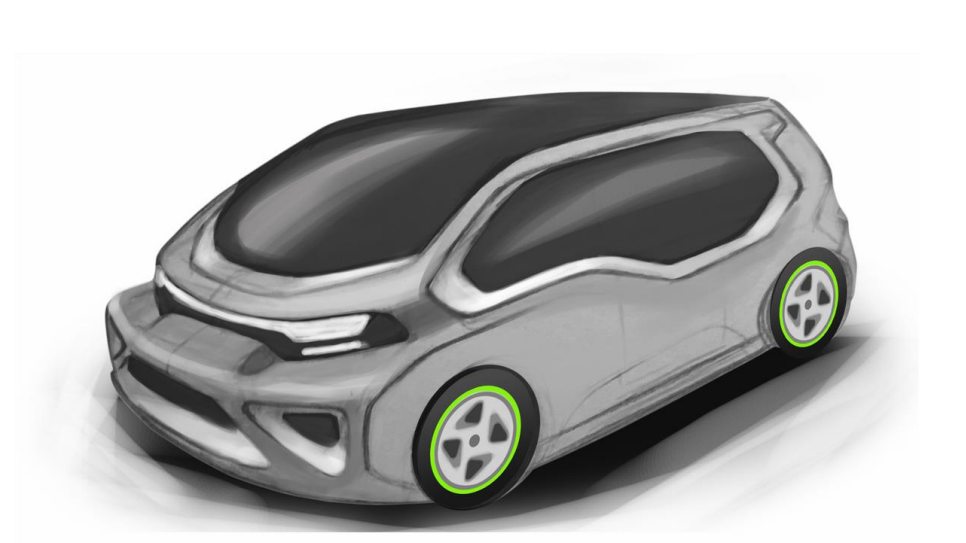

Thus, imagine my astonishment when I recently experimented with an AI tool to create a 3D design of an 8-seater electric taxi. Typing out my requirement took approximately 2 minutes, while the AI promptly produced a 3D design in about 1 minute.

The speed and quality of the render astonished me. I even requested the AI to incorporate a solar roof, and the result exceeded my expectations.

This experience made me realise that AI, in its current evolutionary stage, has a long journey ahead before reaching the point where ‘no job is required’ in automobile design and manufacturing.

If you inquire whether AI will have a role in automobile design and production, my response is affirmative—it certainly will.

Could an automobile be manufactured someday without human involvement? The potential for ‘no job being required’ becomes a possibility after my time…