Volkswagen’s battery subsidiary, PowerCo, is set to transform battery cell production with its groundbreaking ‘Dry Coating’ technology. This revolutionary method is projected to save up to 30% in energy consumption, reduce required floor space by 15%, and slash production costs by millions of euros, heralding a new era of efficient and sustainable battery cell manufacturing.

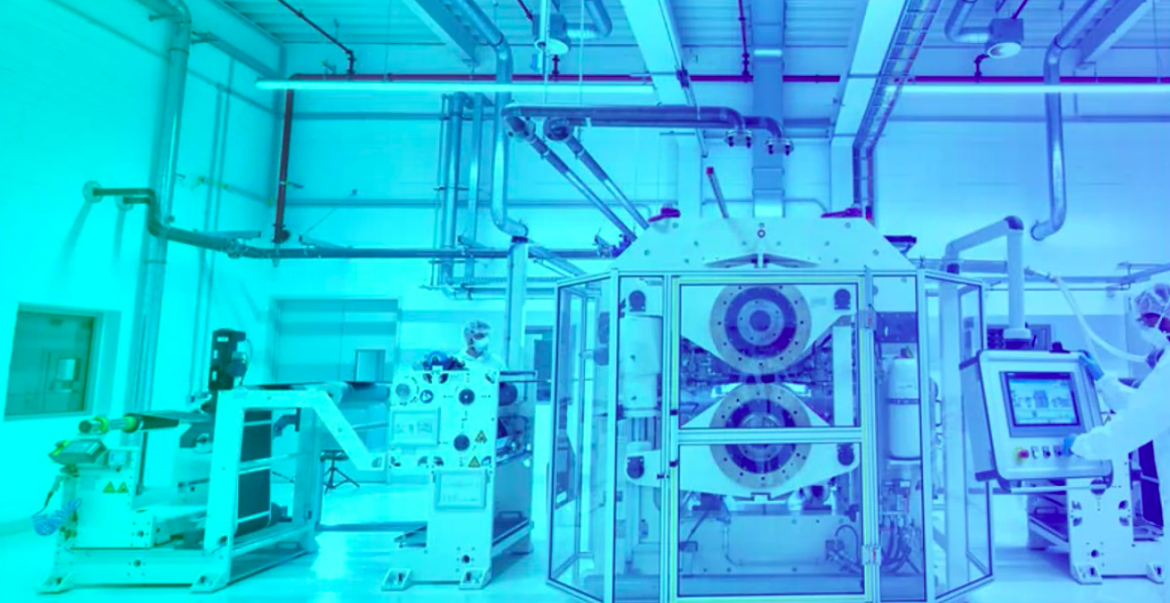

Headquartered in Salzgitter, Niedersachsen, PowerCo is gearing up to implement the Dry Coating procedure across its battery cell production plants in Europe and Northern America. This advanced technique is poised to redefine battery manufacturing efficiency and sustainability on a large scale.

The ‘Dry Coating’ process, in collaboration with German printing machine specialist Koenig & Bauer AG, eliminates the need for energy-intensive wet-coating and subsequent drying. Initial internal tests have already validated its energy-saving potential, reducing consumption by approximately 30%.

Thomas Schmall, Group Board Member for Technology at Volkswagen AG and Chairman of PowerCo, emphasized, “Technologies like Dry Coating showcase PowerCo’s technological prowess. We have the necessary know-how and the right experts to take cell production to a new level and offer significant cost advantages to our customers.”

A crucial aspect of this innovation is the development of a roller press by PowerCo and Koenig & Bauer for the large-scale powder coating of electrodes. This advanced process eliminates the energy-intensive phases and chemical solvent usage that characterize conventional wet-coating methods.

By applying the powdery battery materials directly onto the foil in a manner akin to printing, the Dry Coating technique reduces production steps and eliminates energy-intensive drying furnaces. PowerCo estimates that this advancement will conserve about 30% of energy and 15% of floor space, resulting in annual savings amounting to hundreds of millions of Euros.

Frank Blome, CEO of PowerCo SE, highlighted the significance of Dry Coating, stating, “What the solid-state cell is to the product, Dry Coating is to production – a real game changer.” This innovation not only boosts efficiency but also positions PowerCo uniquely in the market, granting substantial competitive advantages.

The ‘Dry Coating’ procedure’s potential impact is far-reaching. It optimizes energy use, minimizes floor space requirements, and enhances fast-charging capabilities. This monumental shift also reduces the reliance on chemical solvents, ensuring a greener and more sustainable approach to battery cell production.

As Volkswagen pioneers this pathbreaking technology, the automotive and energy industries anticipate substantial positive impacts on both production efficiency and environmental sustainability.