ElringKlinger AG, a leading automotive supplier, has clinched a significant series order for metal battery housings from a prominent global Tier 1 supplier. The battery housings will be utilized in commercial vehicles and city bus applications within the American market.

The five-year series order, valued in the low three-digit million euro range, underscores ElringKlinger’s prowess in the mobility sector. The company will establish new production facilities at its Buford, GA site in preparation for the planned production commencement in 2024.

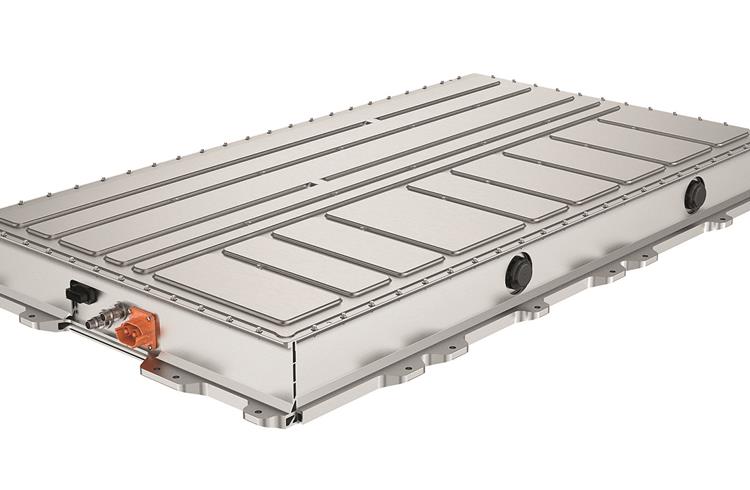

Leveraging its core strengths in acoustic optimization, lightweight metal construction, thermal insulation, and electromagnetic compatibility (EMC) shielding, ElringKlinger has tailored battery housings and related subassemblies for functional optimization based on specific customer needs. The result is a comprehensive product portfolio aligned with the next generation of mobility.

Peter Walker, Vice-President of Metal Forming & Assembly Technology at ElringKlinger, emphasized the company’s global support for battery-electric applications. Drawing on decades of expertise in stamping and forming technology, ElringKlinger ensures top-tier service throughout the product lifecycle, maintaining quality standards through cutting-edge technology and equipment.

ElringKlinger’s legacy in lithium-ion battery component development spans over a decade, catering to various hybrid and battery-electric vehicle models. The company’s proficiency extends to battery systems, modules, and associated components, including cell contacting systems, module connectors, cell covers, and sealing systems.

The acquisition of this substantial series order not only reaffirms ElringKlinger’s position as an industry leader but also underlines its commitment to advancing sustainable mobility solutions.